Globally, the glass industry produces at least 86 million tons of carbon dioxide annually. However, a new type of glass called Lion Glass, developed by Penn State researchers, offers the potential to reduce this carbon output by 50%. Not only does this innovative glass require much less energy to produce, but it also has greater resistance to damage than traditional soda-lime silicate glass. The scientists behind this breakthrough recently filed a patent application, marking the initial step toward bringing Lion Glass to the market.

“Our goal is to make glass manufacturing sustainable over the long term,” said John Mauro, the Dorothy Butt Enright Professor of Materials Science and Engineering at Penn State and a principal investigator on the project. “Lion Glass eliminates the use of carbon-containing admixture materials and significantly lowers the melting temperature of the glass.”

Why is new lion glass important, and how is old glass made?

Soda lime silicate glass, a common glass used for everyday objects from windows to glass tableware, is made by fusing three basic materials: quartz sand, soda ash, and limestone. Soda ash is sodium carbonate, and limestone is calcium carbonate, and both release carbon dioxide (CO2), a greenhouse gas that traps heat, as they melt.

“During the glass melting process, the carbonates decompose into oxides and produce carbon dioxide, which is released into the atmosphere,” Mauro said.

Why is old glass not environmentally friendly?

However, the bulk of carbon dioxide emissions come from the energy needed to heat furnaces to the high temperatures needed to melt glass. With Lion glass, the melting temperatures are about 300 to 400 degrees Celsius lower than normal glass. Resulting in an approximately 30% reduction in energy consumption compared to traditional soda lime glass, Mauro explained.

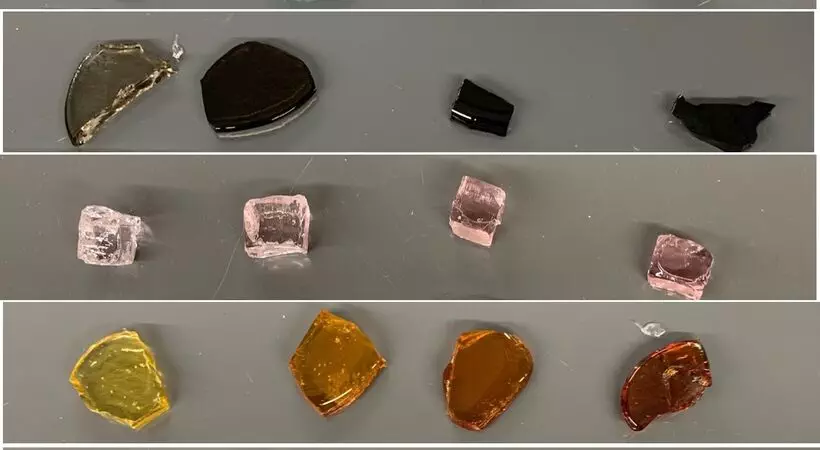

Not only is the new glass better for the environment, but it is also much stronger than traditional glass. The researchers said that surprisingly, the new glass, named after Pennsylvania’s Nittany Lion mascot, had a higher resistance to cracking than traditional glass.

The strength of lion glass makes it better than traditional glass

At least ten times stronger than traditional glass

Some of the team’s glass formulations have such strong crack resistance that the glass will not crack. Even under a one-kilogram force load from a Vickers diamond pipe Lion glass is at least ten times more crack-resistant than standard soda lime glass. Which forms cracks under a load of about 0.1 kg. The researchers are also saying that the limits of the lion’s glass have not yet been found. Because it has reached the maximum load allowed by the indentation equipment.

“We continued to increase the weight on the Lion Glass until we reached the maximum load that the equipment would allow,” said Nick Clark, a postdoctoral fellow in Mauro’s lab. “It simply won’t break.”

Resistant to breakage and cracks

Resistance to cracking is one of the most important qualities to test in glass because that’s how the material ultimately fails, Mauro explained. As time passes, the glass develops small cracks along the surface, which become weak points. When a piece of glass breaks, it is because of the weaknesses caused by the tiny cracks present. He added that glass that is primarily resistant to the formation of microscopic cracks is of particular value.

“Damage resistance is a particularly important property of glass,” Mauro said. “Think of all the ways we rely on the strength of glass, in the automobile industry, the electronics industry, architecture, and communications technology like fiber optic cables. Even in health care, vaccines are stored in strong, chemically resistant glass containers.”

Lighter

Mauro also hopes that the improved strength of lion’s glass means that products created from it can be lighter. Also, because Lion Glass is ten times more resistant to damage than current glass, it can be significantly thinner.

“We should be able to reduce the thickness and have the same level of damage resistance,” Mauro said. “If we have a lighter product, it’s better for the environment because we use fewer raw materials and need less energy to produce it. Even downstream, for transportation, that reduces the energy needed to move the glass, so it’s a win-win situation.”

The new Lion Glass is still undergoing development and research for potential applications

Mauro also notes that the research team is still evaluating the potential of the new glass. They have also filed a patent for the entire glass family. Meaning that there are many compositions within the Lion Glass family, each with its own distinct properties and potential applications. They are also now exposing different compositions of lion’s glass to a range of chemical environments to study how they interact. The findings will help the team develop a better understanding of how lion glass is used around the world.

Mauro also said, “Humans learned how to make glass more than 5,000 years ago. Since then, it has become necessary to move modern civilization to what it is today.” “Now, we are at a time when we need to help shape the future as we face global challenges. Such as environmental issues, renewable energy, energy efficiency, healthcare, and civilization.

The research source is here